2nd guitar – 7th installment

Wednesday

Another great breakfast – sets you up for a good day’s work.

Today was going to be the last day of my stay, although I didn’t realize that we were that close to applying lacquer – which would have to cure for a week, meaning that there was very little I could do to further the progress. And there was no point in paying money to watch lacquer cure.

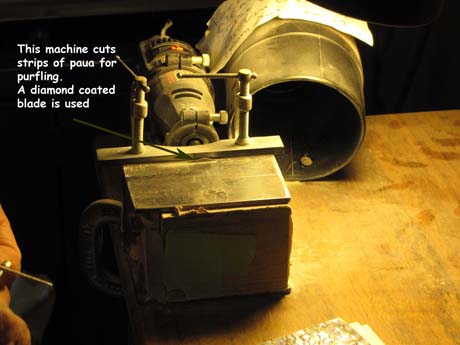

We started by cutting some purfling strips on a neat little miniature table saw, used for cutting sheets (5” X 5”) of paua (abalone glued into a sheet).

The teflon strips that I’ve mentioned earlier were pulled out of the border surrounding the guitar body, and the abalone strips were crushed into the cavity. The strips were glued in place with cyanoacetate glue and accelerator. Then came sanding them flush with the surface of the guitar top, with sandpaper backed by a hardwood block. Sounds easy, but that took a lot of elbow grease – abalone is a lot harder than wood. After that, I was given a razor blade and shown how to scrape the binding. That’s also harder to do than you would think and it took a long time. Dave gave it a final swipe with the razorblade – he has titanium fingers due to his proximity to the aliens that fool around with super-gravity – see Tuesday’s progress – and the binding was pronounced clean enough for spraying with lacquer. “The devil is in the details” as Dave says, and the clean white binding really sets off the cocobolo.

So it was off to the spray booth and the first of nine coats was applied. When the spray hits the surface it doesn’t take long to dry, but this surface is slippery so the first coat is thinner than subsequent ones. Once the nine coats have been applied the lacquer has to cure for a week which means there’s nothing more I could do, except discuss a schedule for the remaining work. So that I did, and left to go back home.

Click on a picture below to start the slideshow….